Soöruz Incorporate Oyster Shells Into Wetsuit Technology

Soöruz has developed a wetsuit that is made from oyster shells; a renewable, recycled and natural alternative to limestone. The new innovative materials Biöprene and Oysterprene will be available from March 2020 and July 2020 respectively.

OYSTERPRENE©: SOÖRUZ integrates oyster shell powder into their top-end wetsuits.

OYSTERPRENE©: SOÖRUZ integrates oyster shell powder into their top-end wetsuits.

As part of the development of the Soöruz Ocean Protect label, the R&D department at Soöruz worked with its suppliers for 2 years to recycle oyster shells into the design of its suits.

Aware of the environmental impact of neoprene, Soöruz has spent the past decade looking to reduce its environmental footprint by developing new materials from renewable and/or recyclable material. Major innovations have included: Soöruz wetsuits with bamboo and recycled polyester (2013), Yulex (2013) and Naturalprene (2016). They all enabled more sustainable wetsuits to be made with no loss of performance.

Sooruz Guru Pro Black

Many wetsuits spotlight limestone as an eco-friendly material. Limestone is a hard, sedimentary rock that is often found in quarries. It limits the use of petrochemical materials, but the extraction process is very energy intensive and non-renewable.

Sooruz Guru Red and black combo- front

Sooruz Red and black Guru combo- Back

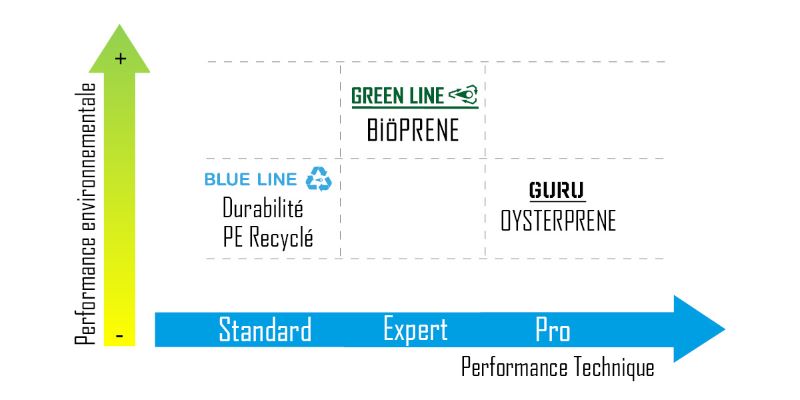

In 2018, Soöruz carried out the first oyster shell crushing tests in France in La Rochelle, France. The results encouraged them to create 2 new materials: Biöprene, which is mainly a bio-based mix of oyster powder, natural rubber, sugar cane and non-food vegetable oil. This material is present in their new Greenline range (available from March 2020) and the Oysterprene©, available from July 2020.

environment vs technique

Oysterprene© is used in Soöruz’s most flexible and efficient neoprene which features in their expert and pro range (Guru, Abyss & Firehead). The manufacturing process consists of replacing the limestone with a natural, recycled and renewable product made from grinding oyster shells. This solution maintains the technical efficiency of the wetsuits whilst helping to improve their environmental footprint, without any impact on cost to the customer. Soöruz are pleased to make this innovation available for big market players, and are proud to know that users will have access to the new technology from winter 2020.