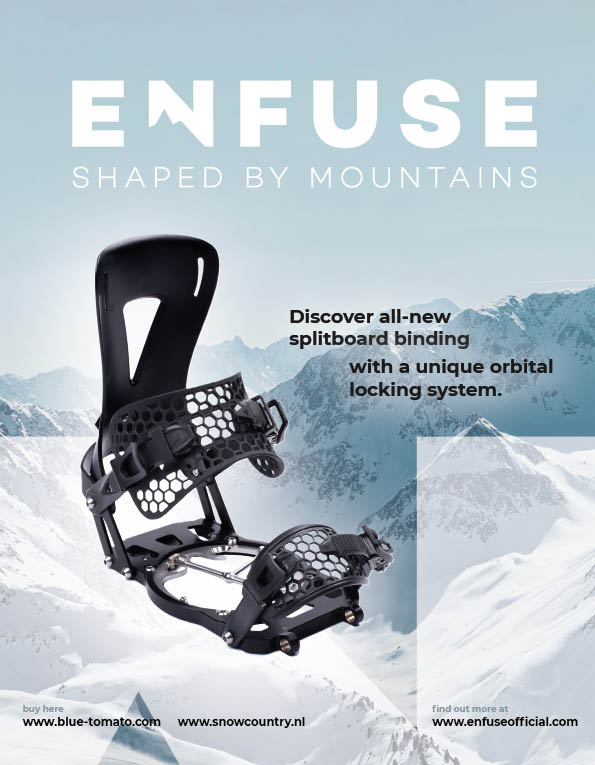

Enfuse Split Binding 2023/24 Splitboarding Preview

Retail Buyers Guide: Splitboarding 2023/24 Retail Buyer‘s Guide

Brand: ENFUSE

Interviewee: N/A

Please provide an overview of how 2023/24 is shaping up for your brand within the splitboard market.

After our first two selling seasons during Covid times, we are now starting a cooperation with retail customers. Our production is mainly going to Blue Tomato and Snowcountry.nl. We are increasing our production capacity and the plan is to grow slowly and under control.

Everyone has been affected by raw materials and shipping prices increases and transport issues. Have you had to make any significant changes with regards to manufacturing, sourcing, or logistics? Are there any examples you can share of how your business pivoted effectively? Any positive developments with regards to these issues and the changes you’ve made?

For our small production the affect of cost increase was significant, but we have been trying to compensate that with our production effectivity. Also some parts need to be outsourced. Prices for 22/23 seasons stays same, but for 23/24, those will need to grow.

After two years of heavy carry over in the industry and more of a return to normalcy last season, what’s your overall sales and production/inventory strategy for 23/24?

As a new brand on a market we have been producing for low stock and high risk. Future strategy is to sell major production on pre-orders and producing low stock. Also we are planning to bring two new binding models. One in 2024 and second in 2025. Both are now in testing phase.

Do you anticipate any shifts in the ratio of e-commerce sales vs. brick-and-mortar sales now that most Covid-19 restrictions are gone? For selling splitboard equipment, are brick-and-mortar retailers especially important?

For us is crutial to let the customers see the binding in person so we are trying to find more customers from brick retailers, but most of our sales are now via the e-commerce.

Does your brand have any new developments concerning sustainability and/or how you are positioning any environmental messaging?

We are trying to produce most of the parts localy to lower the volume of transport. Also our bindings are made from high grade materials, so the durability is as long as possible. Most parts are interchangeble, so customers can repair the binding instead of buying new ones.

Bindings:

Have you made any new innovations in buckles, straps, highbacks, bases baseplates, heelcups, etc.?

We have new lightweight straps, upgraded orbital locking system, to increase durability. Heelrisers have also new design with plastic damper and auto engage feature (with the first step, the riser part lifts form board to position which is more accesable for the ski pole) and the hexagon highback angle adjuster have one position that fully opens the highback for better hiking.

Are you using any new materials in your bindings for 23/24? If so, what, and why?

Whole binding and interface is from airspace Alu 6061 for durability. Some parts of our locking system are from bronze which is better for the durability and also lowers the friction. The pins for hike mode are now tempered so it is more abrasion resistant.

Enfuse 2023

Enfuse 2023

Enfuse 2023