Tiki Wetsuits Designer Phil Bridges Talks Andrew Cotton, Strategy And Growth

Source Talks with Phil Bridges, Designer at Tiki Wetsuits about how their relationship with big wave surfer Andrew Cotton has helped influence and improve their wetsuit design. Bridges also lets us in on their strategies for growth and marketing as well as how Tiki Wetsuits reduce their impact on the environment.

Phil Bridges, Designer at Tiki Wetsuits

Talk to us about your relationship with Andrew Cotton. How big of a part does he play in your R&D?

We’ve known Andrew for years as he grew up round here but we signed him to the team in 2011. Back then he was pushing the boundaries in Ireland with Al Mennie, around the time when Ireland’s big wave potential was being fully realised. He was a well known charger in the UK at that point and soon after was invited to Nazare by Garrett McNamara and began to gain a reputation in the wider world.

He really is integral to our R&D. We are a small team – myself and the pattern cutter design the wetsuits in house before sending patterns and finished prototypes to Sheico for further sizing development and sampling, so we are very hands on with the ability to work directly with Andrew. He comes in at least once a month to give feedback and try out samples. The Zepha model is the direct result of his input and testing and he wears an off the peg suit, the same as any customer would buy. We’ve also produced a number of custom made pieces for him that have influenced that way we approach our R&D – when the success can mean life or death you tend to evaluate every detail.

What are your winter marketing activation plans?

Alongside our regular B2B and B2C communication, we are supporting Andrew’s return to Nazare following his broken back and XXL wipeout win. It’s such a huge story on so many levels, with great media exposure.

Which is your best performing UK market, and where do you see the biggest opportunities for growth?

The outdoor activities and surf school market is very strong for us. We pioneered a wetsuit model specific for this market over 12 years ago and have been continuously refining and improving over the years. Our ADV model is widely regarded as the benchmark wetsuit in this sector and we have seen year on year growth every year since its launch. We are regularly told this outperforms all other suits in durability and for the few suits that do wear out after a couple of seasons, we offer in-house wetsuit repairs to maximise the usage for our customers.

Tiki team rider Andrew Cotton

What have been the biggest changes to your production process in the past 3 years, and how have you overcome these to streamline future processes?

We have had a very stable production for some years now. We believe it is one of our core good business strategies; to have a reliable, sustainable supply. We don’t allow prices to fluctuate wildly or radically change our product year after year.

We do this in 3 ways:

– a strong stable of well conceived, well priced products – no gimmicks or hype

– reliable manufacturing partners – we develop relationships and work with our suppliers

– long term planning to accommodate unforeseen changes such as currency fluctuations and shipping rate increases

How are you combating the radically shifting retail landscape?

We see it as all positives. It’s all about flexibility; ultimately all of the new online commerce options are new opportunities to get your product to the customer.

We are conscientious of the potential pitfalls that online selling represents, particularly discounting, so we apply the same longer term mentality of working with our retail partners, developing trust and building relationships.

Wetsuits are one of a few products where having bricks and mortar shops is essential for getting the right fit. Our carefully nurtured relationships ensure we do not fall foul of showrooming.

What steps are you taking to reduce your environmental impact?

We approach this with the exact same mindset as we do as individuals – we all have a duty to act with responsibly whether as a person or company.

Throughout all of our business activites we aim to choose better solutions whether materials or processes. For example in the wetsuits we use Limestone Neoprene with PAH free glue in the lamination. We limit the use of plastic in packaging where possible and use soy based polybags. We recycle all of our cardboard and ship only by sea. We design our products with longevity in mind and offer a wetsuit repair service (on any wetsuit brand) to extend the lifespan of suits.

These are not billboard green wash campaigns, simply efforts that we take to mitigate our impact where possible. We just consider this part of business best practice.

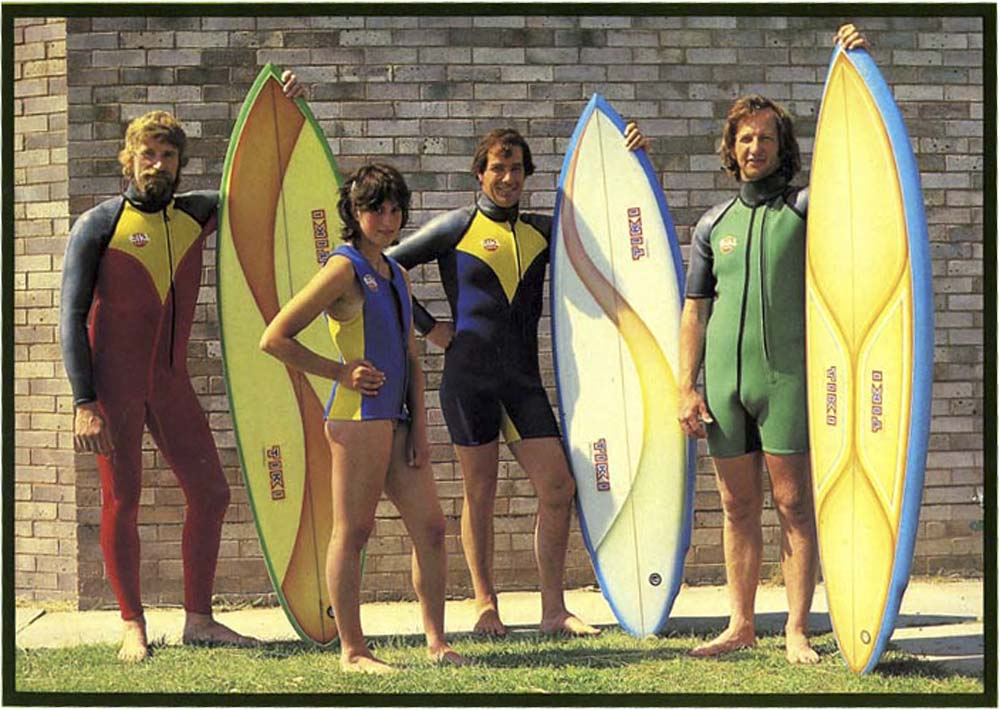

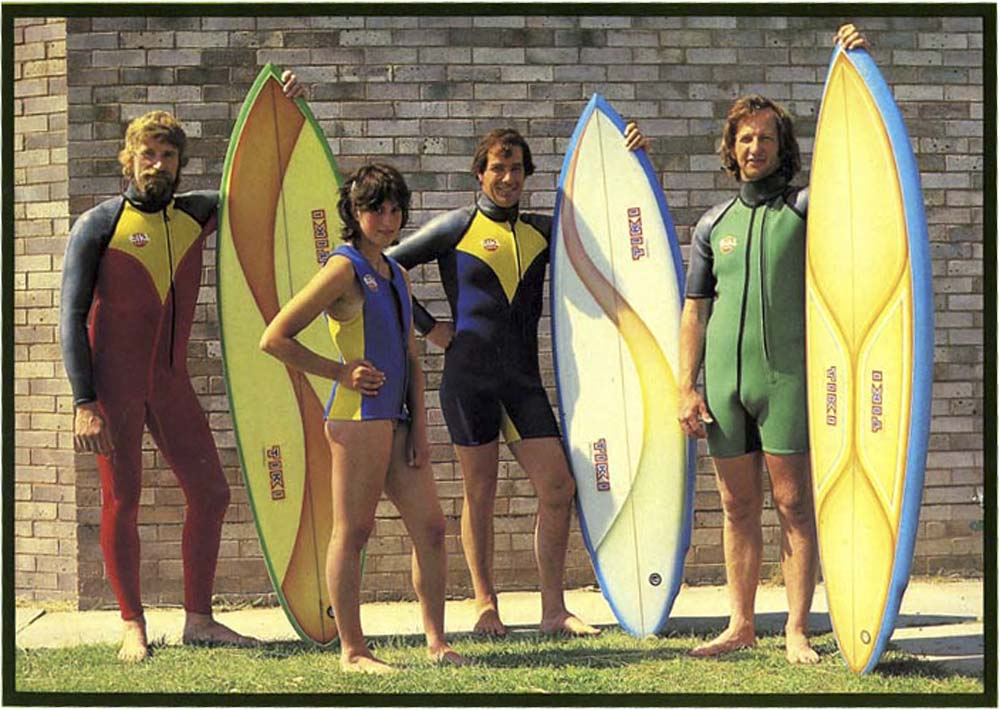

A shot from the Tiki archives

How are you leveraging your heritage to promote future marketing initiatives?

Heritage is something that infuses the whole of the business – our longer term view of the market is largely responsible for our approach of building long term, good working relationships. We are not a flash in the pan business trying to sell the latest overhyped product; our products are well thought out, tried, tested and supported by a wealth of experience.

We’ve been around for 50 years, owned and run by the same directors and our customers gain a lot of reassurance from that.