Gnu 2022/23 Splitboarding Preview

Retail Buyers Guide: Splitboarding 2022/23 Retail Buyer‘s Guide

Brand: GNU

Interviewee: Barrett Cummins

Please provide an overview of how 2022/23 is shaping up for your brand?

22/23 is shaping up to be a live one! GO LIVE! We build our own damn boards, here in WA state at the world’s most environmentally friendly board building facility. At Gnu ideas and artistry are free to bloom in real time in our own little petri dish of radical scientists, retro fools and weird wild magicians. There is no shortage of ideas and creative inspiration here and with the increased demand for all things outdoors, we are hyped to continue innovating and making toys for living. Snowboarding is what we do and what we love. It’s happening now and it’s not in the palm of your hand, GO LIVE!

Everyone has been affected by impacts from Covid-19 in one way or another. Have you had to change manufacturing or sourcing processes and can you explain any good examples of how your business has pivoted effectively?

Gnu snowboards are made in WA at our zero hazardous waste facility. Covid-19 lockdown and factory closure set us back at the beginning of the pandemic but we have been making up for lost time since then. The demand is high but our production costs have increased also, so we are cranking to build to capacity at our factory here in the USA and get as many boards out in the market as we can to meet demand.

Carry-over was a hot topic for 21/22 boards. Where did your brand sit on the matter and has this changed for 22/23?

We moved from having a single GNU splitboard model in 21/22 to having 2 split models in GNU for 22/23. The previous model was a 2 year carry-over but these are new for the 22/23 season and are currently set up to be offered as an early-release in early spring 2022 that will carry through the 22/23 season. Overall, we have fewer carry-over models in our GNU line for 22/23 and we are proud to be offering all new graphics with a couple new models in this new line-up!

The bricks and mortar model is changing rapidly. How are you working with retailers and your ecommerce channel to ensure as little conflict as possible?

This season Mervin added quite a few B+M dealers. In N.Am we saw a 9% increase in dealers across all our brands. Mervin remains committed to our valued specialty retailer partners. Our most successful dealers have a multi-channel strategy, using their websites as a backstop to their physical stores. As the #1 premium supplier in the category, it’s important to us that we’re represented fairly across all our customers’ channels, so unnecessary discounting is discouraged. We have the industry’s best MAP policy (where enforceable) and we never go off price on our own websites, where our strategy is to be the most expensive place on the internet you can buy our products. We hold ourselves to the highest standard, to drive sell through and margin dollars at retail. It’s a symbiotic relationship where Mervin and our partners see the benefit of creating value for our brands

– Maxx Von Marbod, Mervin Sales Director.

What’s your company doing to improve its carbon footprint/eco consciousness?

We have always been building boards in a zero waste, eco-friendly facility here in WA State, USA… even before it was trending to have an eco-conscience. The Mervin factory sits at the base of the Olympic Mountains, is wind and water powered, uses non-toxic materials, fast growing woods, water-based inks, we recycle our wood and plastic off-cuts and we continue to source emerging earth friendly materials while improving our production processes. This is our business model for snow, ski, and surf. We are the largest US based board manufacturer (snow and surf) and we take our carbon footprint seriously. Not just because it’s trending but because our friends work here, our children are growing up in this community, and we want to protect our environment so we can continue to work/play/grow in this place without destroying it.

Are you using any new materials in your hardware for 22/23? If so, what, and why?

We are sticking to snowboards with our GNU splitboard line. We aren’t making skins, poles, or any of the accessories for splitboarding, we are focusing on what we do best. The Gnu Banked Country and Barrett splits feature Karakoram Ultra clips to lock the boards together for speedy, smooth transitions. Aspen structure beams built into the core to ensure stability in all conditions and integrated 3-D clip inserts that allow us to avoid any drill through interruptions of our smooth sintered bases. The Banked Country and The Barrett splits have the same advanced tech features as their solid counterparts. Progressive Magne-Traction edges are a proprietary Gnu technology currently only used in these boards. The progressive Mag’ allows for a smooth entry turn and the grip where you need it at the tail. These boards often find themselves in powder so there is less of a need for additional edge grip at the nose where you initiate your turns. The mag bumps deepen progressively toward the tail to keep your turning radius solid and avoid sliding or skipping out of turns. The secret is in the subtleties

Any big advancements in functionality? Skinning, transitions, etc, as well as riding?

A unique feature in the Barrett split is the addition of Vectran Power Pop Bands in the Tri-ax/Bi-ax glass configuration. This is something Barrett worked on with her solid board and it allows the board to be snappy and stable without adding weight or stiffening up the flex. It’s been a magic band of energy that makes the board lively and responsive, and it is also integrated into the Barrett splitboard construction.

Which area of the market do you primarily cater to, price-wise? Has this changed at all in recent times, or is it pretty consistent?

We are catering to a more premium market with our USA made boards built with eco-friendly processes and materials. We have exceptional quality, unique proprietary tech, and performance product…made by us (snowboarders, surfers, skaters, and skiers) in our own zero hazardous waste factory. Since Day One.

Please tell us about the dominant visual themes in your 22/23 gear, including any interesting artist collabs you have lined up?

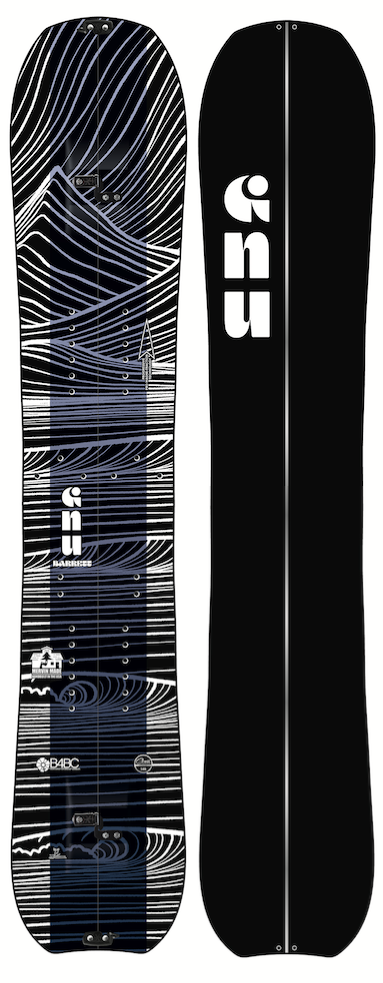

The Gnu splitboards are tied to their solid counterparts with the Banked Country and Barrett boards. The Banked Country board is designed in partnership as a “father/son” board with Temple and Cannon Cummins. Cannon did the resin artwork featured on the Banked Country and Banked split. It was inspired by the storm maps that track the snow and swell that are central influences on life in the PNW. The artwork on the Barrett and Barrett split features art by Jonas Claesson. His line art flows like water from the mountains to the ocean. A color wash of light purple to teal blue running the length of the board keeps the vibe icy cool

Most brands tell us that selling in store is really important for splitboard gear, as it’s where you can get good advice. Can this be maintained post-COVID, or will you be looking to find more customers online?

We fully support the specialty retail buying experience. Our dealers have made important adaptations to their physical retail space which has improved the purchase experience from a safety perspective as well as merchandising and shopping space for a fun educational time in the store. Those customers who also wish to find product online will find more informative product videos, explaining product features & benefits, with engaging team-driven action. The lines have blurred between pure Brick & Mortar and pure Internet. Most customers, particularly those looking for premium product, are doing their homework online, then shopping in-store to make a final decision

What are your three biggest European markets for splitboard hardware?

Our biggest market for Splitboards is Germany followed by strong sales in Switzerland

Hero Products

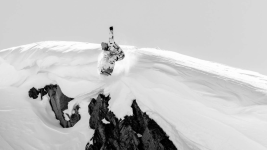

Temple and Cannon’s Banked Country split is a resort carving pow slaying machine transformed into a lightweight climbing, powder, and adrenalin access tool. A radically refined directional geometry/shape with a floaty nose, mild taper, Banked Slalom winning side cut and their unique progressive “teeth in the tail” Magne -Traction for quiet turn entry and unbelievable hook up in the tail

2223-banked-country-split

Barrett took her refined all terrain directional pow slaying resort ripper and turned it into the ultimate split stick. A floaty nose keeps you on top of things, the cambered body and lightweight Paulownia core enhanced with Vectran power bands ensures great traction for easy climbing and pop and power in all that powder. Progressive Magne-Traction guarantees smooth entry turns and amazing hook up in the tail for controlled turns

2223-barrett-split