Gore-Tex SS20 Eco Textiles Preview

Retail Buyers Guide: Eco Textiles SS20

Brand: GORE-TEX

Interviewee: PR Team Gore Fabrics

What are your two most recent sustainable innovations and what makes them more sustainable than equivalent alternatives?

We already transferred more than 50% of our Garments laminates to a DWR that is free of PFCs of Environmental Concern.

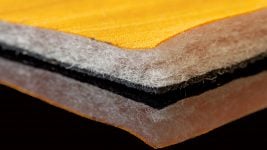

In A/W 2018 we launched a 3-layer GORE-TEX jacket that comes with a PFCEC free DWR and a solution dyed and recycled backer material

What was the initial driver behind investigating these sustainable innovations?

Gore Fabrics is committed to continuously improving the environmental impact of its products. Part of this effort are our PFC goals we set ourselves in February 2017. Gore Fabrics intends to eliminate PFCs of environmental concern from its consumer fabrics products. By implementing an aggressive innovation program, Gore is working towards the elimination of PFCs of environmental concern from the life cycle of its consumer products by 2023. This applies to our Durable Water Repellent (DWR) treatments and our membrane manufacturing processes.

What is your company’s definition of a more sustainable (ecological and social) product/material?

Our environmental approach is based on sound science, Life Cycle Assessment and durability of our products. To ensure this happens, we have been using Life Cycle Assessment (LCA) for more than 20 years.

Our LCA results have shown that the best way to minimize the environmental footprint of a functional outdoor jacket or a pair of hiking boots is to enhance their durability.

This is why quality, durability and performance are the cornerstones of our products. When it comes to material choices we strive to offer products with an optimized combination of functionality and sustainability for its intended end-use.

LCA not only helps us to identify approaches that really matter when it comes to reducing our impact, but to provide our partners with an ecological balance sheet that informs their environmental strategies.

How do these innovations contribute to the circular economy, if they do?

When it comes to material choices we strive to offer products with an optimized combination of functionality and sustainability for their intended end-use. As we see durability as a key influential factor for reducing the environmental impact of a product, we encourage our customers to properly wash (and care) for their products, and to prolong the life time by repairing them.

Furthermore, we are constantly increasing our recycled and solution dyed material offer.

Also, we’re an active member of the Ellen McArthur foundation whose mission is to accelerate the transition to a circular economy.

What are the ecological and social topics within your value chain and how do you take care of them? (certifications and standards, code of conduct, sourcing guidelines)

Please have a look at our Responsibility Updates: where you can find more information on the following topics:

- Our expanded offering of recycled and solution dyed textiles

- Our wash and care pilot

- Our cooperation with Patagonia’s Worn Wear Tour

- Our significant progress in Gore’s GSR Program (Gore’s Guidelines on Social Responsibility)

What are your greatest challenges and achievements for ecological and social improvements? (social and environmental projects, ecological footprint reduction)

The significant progress we made towards our goal of eliminating PFCs of Environmental Concern from our consumer products. You can find more information here:

Please tell us about any multi-stakeholder initiatives you’re involved in (roundtables, working groups, industry organizations)

- Ellen McArthur foundation

- Sustainable Apparel Coalition (SAC) and Social & Labor Convergence (SLCP)

- (we are a founding member, see Responsibility Update)

- Outdoor Industry Association (OIA -> NA)

- European Outdoor Group (EOG) and Outdoor Microfibers Consortium

- Fair Labor Association (GORE® WEAR and SITKA Gear)