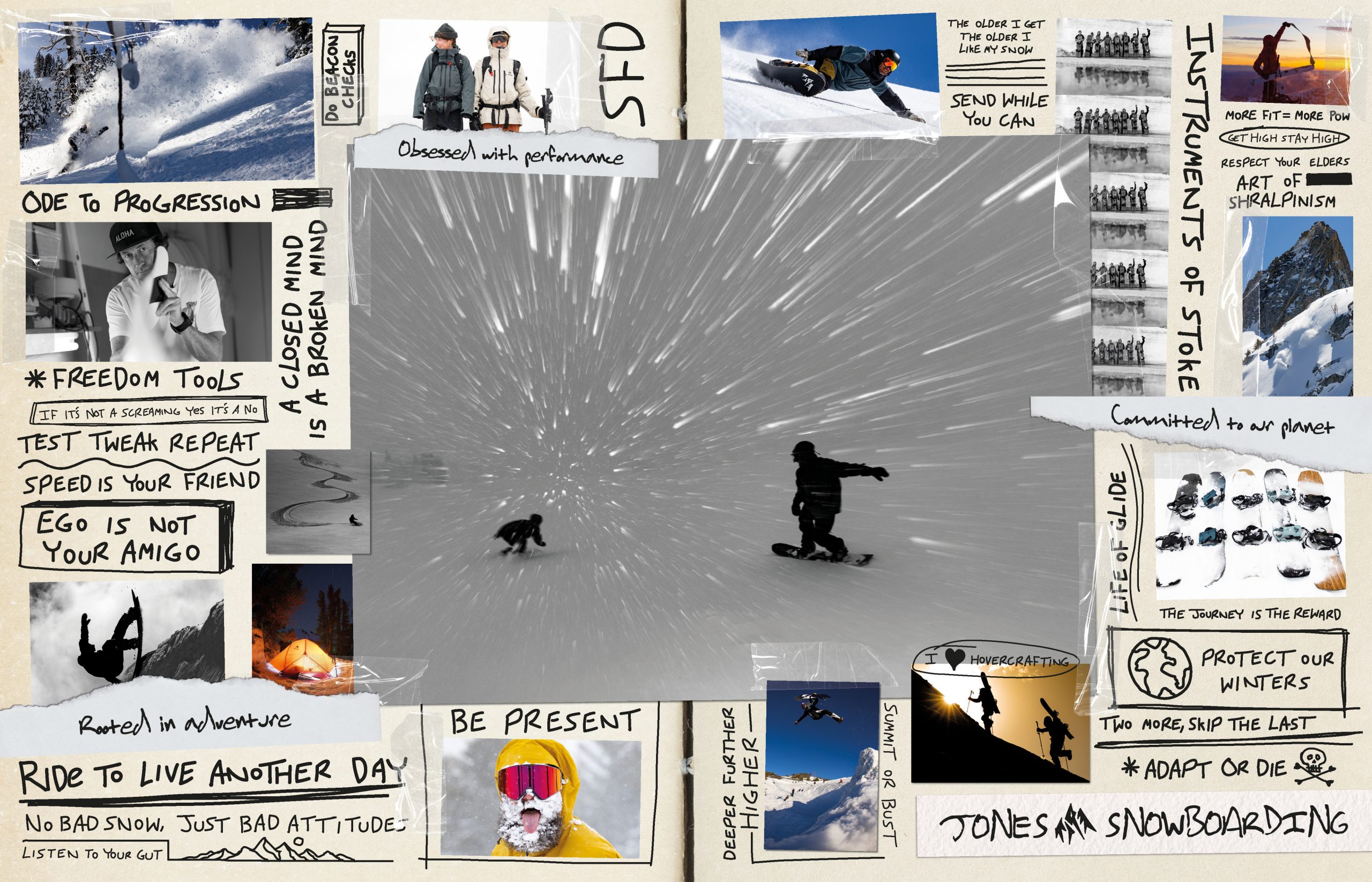

Jones Snowboards Introduces Re-Up Tech: A Revolutionary Snowboard Recycling Programme

Sustainability is now, thankfully, at the forefront of most brands minds when it comes to manufacturing and Jones Snowboards looks to have upped the game with the launch of the world’s first snowboard recycling programme: Re-Up Tech. We grabbed Ruairi Collins, European Marketing Manager, to discuss what’s behind the new innovative programme.

How have things been going for the brand since we last talked?

All is well at Jones. We’re excited about all the new developments in both our hardgoods and softgoods lines, and we’re grateful for the continued support from riders around the world that allows us to keep growing as a brand. The launch of Re-Up Tech and our snowboard recycling program is especially gratifying as we’ve been working on ways to recycle snowboards for many years now.

This season sees the launch of Jones’ new innovative Re-Up Tech – the world’s first snowboard recycling programme, can you give us a brief overview of what’s involved?

Re-Up Tech stands for recycling old snowboards and upcycling the materials into new snowboards. The process begins by collecting old boards that are no longer usable. We then remove the metal edges and inserts for recycling, lightly sand the topsheet and base to remove oil and dirt, stack and glue six boards together, slice the stack to create a thin piece of material that includes layers from all six boards, then use the slice in the wood core of new boards in place of stringers.

What made you decide to set up the programme?

We are always looking for ways to reduce the impact of our gear, and we got serious about finding a way to recycle snowboards after completing a Lifecycle Assessment (LCA) that calculated a snowboard’s “end-of-life” impact. Throwing a board in the landfill or incinerating it as they do in Europe has a notable carbon footprint. Re-Up Tech helps us reduce these end-of-life impacts and keep snowboards out of the landfill.

What snowboards can be used in Re-Up Tech process?

We can recycle any brand, model or year snowboard. The board just has to have a wood core, and ideally isn’t broken in half.

Have you found using recycled wood as a stringer, rather than the more traditional use of carbon fibre, affected the performance of the boards in any way?

Re-Up stringers absorb vibrations and are more torsionally stable than any stringers we’ve tested. The orientation of the stringer at 90° relative to the wood core makes the stringer much more effective at dampening and adding pop. It’s the perfect stringer for boards with extended nose shapes like the Hovercraft 2.0.

What range of Jones’ boards will feature Re-Up Tech?

The Hovercraft 2.0 snowboard features a nose stringer in the wood core made with Re-Up Tech.

To kick start the process you’ve set up an incentivised collection programme for customers, how does that work?

Our snowboard collection program offers riders two ways to return their retired boards for recycling. You can either ship the board back to us with a prepaid shipping label, provided by us, or you can bring the board to one of our participating collection partners.

We offer free ground shipping to customers in the continental United States and select European countries.

If you ship your board back to us through our website, you will receive a $50 or 50€ credit towards the purchase of a new Jones board. When you return a board to one of our participating collection partners, if an incentive is offered, it will be determined by that Jones dealer.

Will you allow other brands to use the technology in the future?

Re-Up Tech is a proprietary technology to Jones at this time. When our processes and supply chain are established, we will share it. Right now, the limiting factor in how quickly the technology will grow is finding enough truly dead boards to recycle. We don’t want to recycle boards that could still be ridden if they were tuned.

What are your hopes for the programme, and the snowboard industry in general, over the coming years?

Our goal is to make the ski/snowboard industry more circular by keeping as many boards as possible out of the landfill or incinerator. We strive to find value in old boards by upcycling the collected materials and giving them a second life in a new board. To achieve this goal, we know we’re going to need the support of the entire industry so we look forward to sharing Re-Up Tech with more brands as soon as possible.

View products from Jones’ 2024/25 lines: