PrimaLoft Forms New Partnership With Parley For The Oceans

In an effort to reduce the volume of new fossil oil-based materials being produced, PrimaLoft Inc. and Parley for the Oceans have partnered to create high-performance insulation from existing plastics. Successful engineering means that plastics collected from the oceans and beaches can be re-purposed into high quality products.

Press Release:

PrimaLoft, Inc. Announces Partnership with Parley for the Oceans

Advanced material technology experts will turn marine plastic waste into high-performance insulation materials

Today, PrimaLoft Inc. and environmental organisation Parley for the Oceans announces a strategic partnership that will take plastic intercepted from remote islands, beaches and coastal communities and use it to manufacture high-performance insulation products. PrimaLoft, the experts in advanced material technology, will be the first insulation provider in the textile industry to partner with Parley to develop products from marine plastic waste. This represents another step forward for PrimaLoft in its efforts to be Relentlessly Responsible™.

According to a report published by the United Nations, 8 million tons of plastic ends up in the ocean per year. This enormous amount of plastic pollution has a tremendous impact on marine life, as it costs the lives of 1 million seabirds and 100,000 marine mammals yearly. The economic consequences are also immense. Each year, plastic causes $8 billion in damage to marine ecosystems. Parley and PrimaLoft are both committed to taking action that will positively impact this significant environmental issue.

“This collaboration with Parley is a perfect match. We both have the same goals: reducing the plastic pollution on our planet, especially in the oceans,” said PrimaLoft president and CEO Mike Joyce. “Avoiding the production of new fossil oil-based materials wherever possible is also a top priority. After the launch of PrimaLoft® Bio™ and proving that our fibre is ready to be utilised in a circular economy, this is another important puzzle-piece in our sustainable efforts.” In addition to the material PrimaLoft sources, the company also supports Parley in its projects preventing ocean pollution all over the world.

Parley now operates a pioneering global supply chain and Cleanup Network across 28 countries, intercepting plastic waste from beaches, islands, and in remote coastal communities. In 2015, the first products made with Parley Ocean Plastic® put the marine plastic pollution crisis into the spotlight and presented a unique solution to a complex challenge – one that diverges from traditional recycling approaches.

“Parley Ocean Plastic® is a trademark for a range of premium materials to turn products into Symbols of Change and fund our battle against marine plastic pollution,” comments Cyrill Gutsch, Founder and CEO of Parley for the Oceans. “The enormous success of our partnerships with brands like adidas and Stella McCartney, internationally renowned athletes, artists, and entertainers has had a carry-over effect on the whole industry. Recycling is now sexy, desirable and stands for meaningful design. Purpose is the new luxury. Today we welcome PrimaLoft as an official Parley supply chain partner to our global network, adding new high-performance material types to our portfolio and drastically supporting the growth of our movement – for the oceans.”

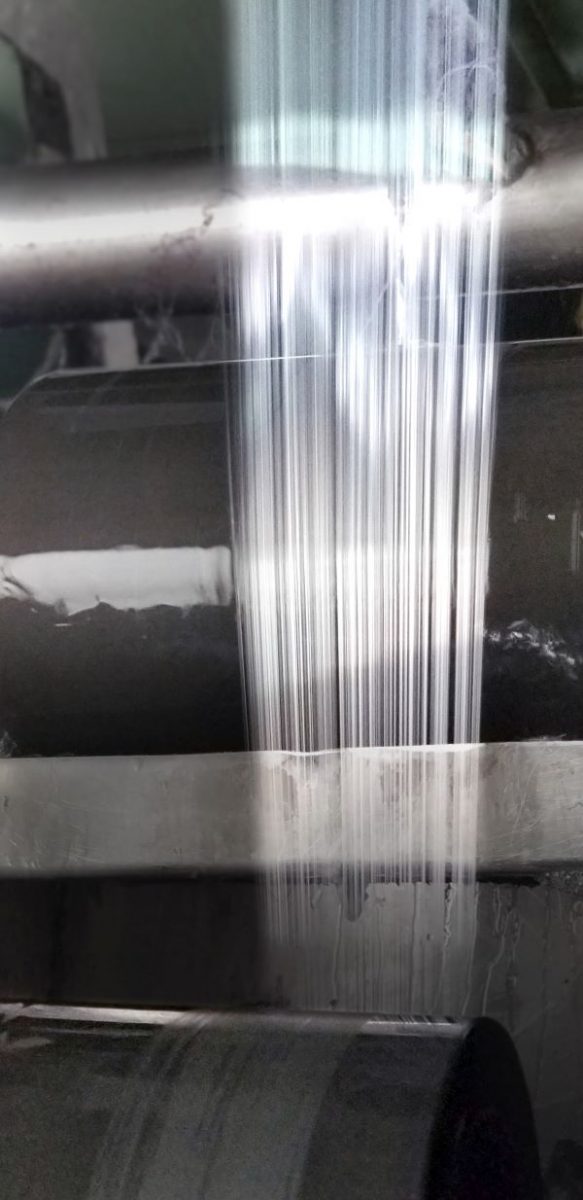

From plastic waste to high-performance insulation

“Using upcycled marine plastic waste to create insulation that meets the high-performance standards customers expect from PrimaLoft presents a unique challenge,” said Mike Joyce. “Sourcing high-quality raw materials is essential to the development of our insulations, and marine plastics are often lacking that level of quality. Together with Parley, our engineers have developed a method that allows for marine plastics to produce insulation products that meet our high-performance standards.”

In addition, PrimaLoft will make its best efforts to incorporate and implement the AIR (Avoid. Intercept. Redesign) strategy, ultimately leading to a reduction of the company’s plastic footprint in an effort to join forces in the fight against marine plastic pollution.