Wing S/S 2025 Retail Buyer’s Guide

Performance of wings has been stepped up with the development of new premium materials. The next step is to play with fabric combinations and new constructions that will push the boundaries even more. Exciting times for brands, retailers, and consumers. By Rocio Enriquez.

Wing foiling is maintaining the good health of the water sports industry with its accessibility for newcomers, and the performance possibilities for seasoned riders. Those at the higher end of the ability spectrum are happy to spend on innovation, and wing brands are responding with ongoing R&D. After a few seasons welcoming new materials, the focus is now on the different combinations and wing constructions to make the most out of them. The goal is the perfect balance between weight and rigidity, but always keeping an eye of affordability. We want tighter canopies and stiffer struts that are light and do not cost us an arm and a leg.

The use of premium fabrics such as Hookipa and Aluula is commonplace, sometimes mixed with standard fabrics to enhance performance. There is a conversation about the need to innovate existing wing shapes, panelling is the most obvious response. Developers are changing panel layouts and playing with seams to explore new options. The debate over hard versus soft handles is still very much alive. However, the trend is to explore the use of both to cater to different riding styles. There is a steady demand from entry level riders, a segment with growth potential. Nonetheless, the main demographic for wing sales is composed of water sports enthusiasts that transition into the sport. These are intermediate to advanced riders that prioritise performance and innovation. Bestsellers charts are topped by all-round wings that cater to all levels of riding and can perform in various conditions. Smaller sizes tend to go to kids and strong wind riders, while larger sizes are sold to heavier users.

2025 Wings

Premium materials are becoming more prevalent, but they are not replacing standard ones. They come at a much higher price, and brands are trying to balance their offering with more affordable options to keep newcomers coming into the sport. Dacron is going nowhere for now, and we start finding it mixed with Aluula, Hookipa, or Penta TX in certain models. Mistral keeps using Dacron on their bestsellers, while combining it with Hookipa for the leading edge and fuselage strut on their Skywave range. Naish has developed a premium version of their versatile ADX Wing Surfer. The ADX NVision boasts a cutting-edge Helium frame construction made with Aluula, making it very lightweight and stiff. Vayu is testing a lot of materials as well as different combinations.

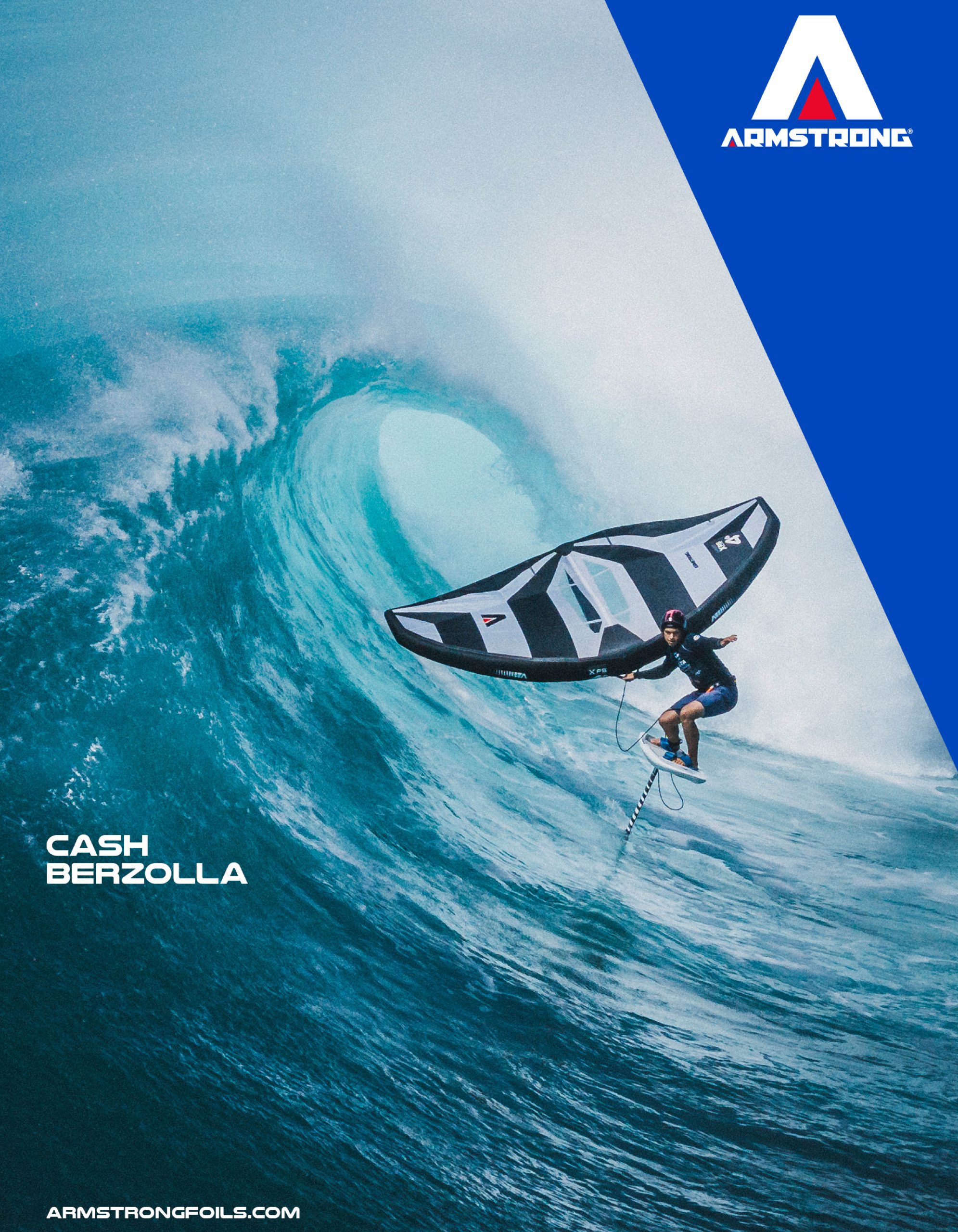

The Aura X leads their offer, mixing Aluula on leading edge and struts with Tenjin canopy. Neilpryde is continuously improving their products that feature Aluula. At the same time, they are also developing more cost-effective high-tech materials that can offer a similar performance at a more affordable price. Seaflight focuses on durability and affordability. They offer DK50 double ripstop nylon canopies and KPE175 Dacron struts. Armstrong’s A-Wings are made from the latest generation Dacron and Ultra PE reinforcements, focusing on construction techniques to improve performance with their XPS Lightwind wing featuring the patent-pending Power Batten. This is a premium carbon bar located at the rear of the canopy and perpendicular to the strut. It dramatically improves airflow and canopy stiffness in larger sizes, making it an easy to fly design for such a large area. “Its performance in single digit breezes is truly awesome and really unlocks another level of riding”, says Kjell van Sice from Armstrong.

Seaflight announces a transition to lighter design for their bigger sizes, with slightly different features. Many brands are experimenting with design tweaks to improve performance, the two areas of construction that are getting more attention from product developers are panelling and handles. NSP sticks to Dacron and focuses on innovative panelling methods to reduce weight and maintain responsiveness. “Developers are exploring radical new shapes, with innovative canopy panelling methods and optimised support for the strut, as well as the leading and trail edges, resulting in enhanced aerodynamics and control”, says Jarra, in charge of design at NSP. Handles are a hot topic with no clear winner between soft and hard options, as they each cater to different performance demands. Brands are quite experimental in this area to cater for different user groups. Neilpryde has introduced the new NP Mono handle that functions like a boom while adding the drop grip feature. This provides their new Firefly wing for freestyle and surf with improved rotational manoeuvres. “The Firefly combines the NP high lift concept with a significantly reduced wingspan and a simplified airframe with a stiffer feel, making it a strong contender for 2025″, announces Hendrik Holzhauer.

Seaflight also looks at wave riding, updating their SurfWing with soft handles. Naish has given their Matador LT 2.0 a handle conversion system. It comes with hard handles mounted, and with an extra set of soft handles that can be easily interchanged. Hard handles for a more direct, rigid feel, or soft handles for riding freedom; you can adapt the wing to your personal riding style.

Sustainability

Sustainability efforts are focused on packaging and product lifespan. You will find very few wings packed with single use plastic with Mistral, Naish, and Vayu manifesting their commitment to this. NSP is reusing cut-off materials from production for their wrapping and packing. Seaflight packs their wings in paper or cardboard and builds their wing bags from recycled materials. Vayu is testing how to reuse leftover cut-offs in their production next year. They are working with a few options that have a high percentage of re-worked materials.

Durability is a powerful ally to sustainability. A longer lifespan reduces production demands and material sourcing. Neilpryde makes this their top priority in their commitment to sustainability. Not only do they choose the most stable and durable materials, but they offer guidance about how to repair minor damages to their Aluula struts. Seaflight also designs their wings to last longer than one season, using the best materials for that purpose. Finding sustainable factories for production plays an important role, but it’s not always easy as it depends largely on the country where the factory is located, and whether it has any regulations in place which are lower in Asia. Concentrating production in one location is the way Naish limits their footprint. Their centre of operations is powered by solar energy. So is the production facility that builds Vayu’s wings.

Retailer Support

There are several ways in which brands are supporting their retailer’s sell-through, an important barrier to overcome is the possibility to test their wings. Vayu, Seaflight and Neilpryde offer demo wings that retailers can directly offer their clients for testing or use in demo events. Naish relies on a big team of experts and sales reps in every country to offer on-site support to their dealers. Mistral has also increased their staff for this purpose, they add to that an online portal that streamlines the ordering process. With such a technical and innovative product, retailer education is important.

Armstrong focuses a lot of their marketing budget in building educational resources around wing design, product selection, and overall sport education. These initiatives are add-ons to tried and tested methods such as social media presence, endorsement from team riders, and in-store and online imagery assets. Delivery models are also adapted to best support retailers with Naish offering a fast delivery system in most of the EU in twenty-four to forty-eight hours. Vayu allows orders from stock, with pickup at their facility or even collection at events. Seaflight streamlines their range of products available from stock that can be ordered in small quantities or drop shipped to retailers’ customers. Armstrong keeps a healthy stock, so they can fulfil orders as they come. Neilpryde offers two ordering systems. Retailers can place orders directly through their B2B shop for products stocked at their warehouse in Germany. For larger orders, they can place ex-works orders directly from their factory. This allows the retailers to manage their logistics according to their specific needs. With users keen to spend on innovation and brands delivering it, retailers can look forward to a quick sell-through of wings.