Südwolle Group SS20 Eco Textiles Preview

Retail Buyers Guide: Eco Textiles SS20

Brand: Südwolle Group

Interviewee: Elisa Pfeiffer, Marketing

What are your two most recent sustainable innovations and what makes them more sustainable than equivalent alternatives? (for this summer season, we are mainly promoting this one innovation)

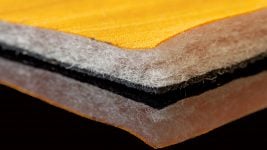

What’s currently trending in our product portfolio are the so-called ‘Betaspun Evolution’ qualities. These yarns are spun using our Betaspun technology, where we twist a filament around a Merino base. What makes the qualities now ‘evolved’ is the usage of natural fibres, like cotton, silk or viscose, and sustainable fibres like biodegradable polyamide as a filament. As a result, we have a durable, lightweight and comfortable yarn that is 100% biodegradable!

What was the initial driver behind investigating these sustainable innovations?

The environment is something that concerns us all – no matter if you are a wool supplier, textile producer, a brand or an individual consumer who buys clothing. For us, it is a long overdue trend with a great deal of new and interesting opportunities and a basis for innovation. And the trend continues to grow, our consumers are increasingly asking for sustainable alternatives. This and our own hunger to make sustainability the norm instead of the ‘add-on’ encourages us to do more for our ecological and social environment.

What is your company’s definition of a more sustainable (ecological and social) product/material?

Sustainability for us means ecological awareness in three fundamental aspects. Firstly, the efficient optimisation of the production process, e.g. by using as little water and electricity as possible. Secondly, the use of sustainable materials, explicitly wool, as it is both natural and biodegradable. Lastly, with regard to the life cycle of our products, reuse and recycling.

How do these innovations contribute to the circular economy, if they do?

Merino wool itself in an amazing fibre. It is grown naturally on sheep and is not – like most man-made fibres – derived from not regenerable crude oil. At the end of its lifecycle it biodegrades completely and does not contribute to microplastics pollution within our oceans.

By the way, if you want to prolong its lifecycle – no problem! Although wool only makes up a 1.3% market share in the total fibre market, among recycled textile fibres wool holds a 5% share. This indicates that wool items are of higher quality and durability to be lasting longer in order to perform in their second life. Additionally wool is a valuable fibre very well suitable for the recycling process.

We can of course blend wool with other biodegradable fibres like cotton, hemp, linen, silk, or biodegradable polyamide or recycled fibres, for example recycled polyester or nylon, depending on performance aspects. This way, we want to further foster the ‘closed-loop’-way of producing textiles.

What are the ecological and social topics within your value chain and how do you take care of them? (certifications and standards, code of conduct, sourcing guidelines)

We work with a variety of different regulations, such as the Global Organic Textile Standard, IVN Best, bluesign, ZDHC and many more RSLs (Restricted Substances Lists) and MRSLs (Manufacturing Restricted Substances Lists) which are directed to us by customers. In total, we organize over 50 different lists defining the guidelines for production!

As a result, in order to replace many chemicals in recent years, we had to form new processes and a team that understands the highly complex chemical requirements, which has been the biggest challenge. For us, this was and is a long and technically demanding process.

What are your greatest challenges and achievements for ecological and social improvements? (social and environmental projects, ecological footprint reduction)

One great achievement we can celebrate is Naturetexx® Plasma. It is a chlorine-free treatment that we have developed over the past 10 years in our innovative plant in Germany to make the end product suitable for machine washing and drying, using only electricity and air during the treatment process. In this way, we can avoid the presence of chlorine in our wastewater during processing.

We have invested several million euros in the intensive development phase of Naturetexx® Plasma, including investments in machinery and personnel costs. And it was worth it! Not only because we can now offer a chlorine-free alternative for wooltop processing, but mainly because our customers are actively asking for it.

Over the past few years, we were able to realize an increased demand for such yarns which are produced with respect and value for the environment. Generally, working together with customers on ecological topics has become a crucial part of our daily business. Increasingly, more customers are looking for sustainable alternatives like Naturetexx Plasma®. And, in some cases, companies have replaced their conventional treatments for whole product ranges with this innovative treatment and are incredibly happy with it.

Please tell us about any multi-stakeholder initiatives your involved in (roundtables, working groups, industry organizations)

We work closely together with a wide variety of organizations like The Woolmark Company, the International Wool Trading Organization, ZQ Merino and many more.

We generally benefit from our position right at the middle of the supply chain and from being able to connect a huge network of experts. Establishing long-term partnerships instead of simply ‘selling’ is crucial for our sustainable future.